Activity areamAbs & RP

Monoclonal antibodies and recombinant proteins: from screening to pharmaceutical release

Substances produced using genetic recombination are a heterogenous body of pharmaceuticals based on genetic editing on cells. They are further used as substrates for the manufacture of these advanced therapeutics.

The Clean Biologics group has taken part in their development through Clean Cells, companie specializing in the quality control testing of these biopharmaceuticals according to GMPs with an extended panel of assays used from the screening stage to the commercial phase.

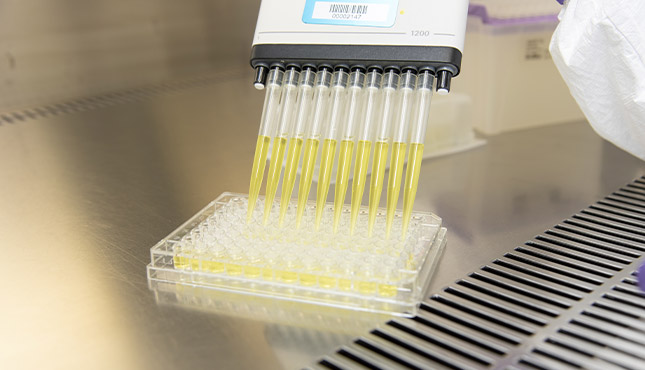

Monoclonal antibody screening support

Clean Cells has developed numerous methods used for the early screening step, helping customers select the most suited validated methods used to assess antibody-dependent cytotoxicity (“Antibody Dependent Cellular Cytotoxicity” or ADCC assays), or complement-dependent cytotoxicity (Complement Dependent Cytotoxicity or CDC assays)

GMP-compliant quality control testing

Clean Cells is a worldwide leader in the regulatory quality control testing of clinical and commercial lots.

We take part in the full characterization of monoclonal antibody and recombinant proteins manufacturing chains at key-steps, from starting material to final lots.

Please visit our dedicated webpage for more information.